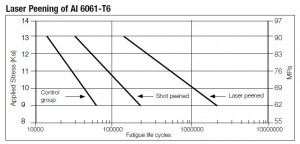

Laser peening can surgically place exceptionally deep residual compressive stress into key areas of a component to retard crack initiation and growth enabling increased fatigue strength ratings.

Laser peening is not a replacement for controlled shot peening, but has additional advantages that can influence which method to use.

Laser Peening is been used to prolong the fatigue life of critical aerospace components such as turbine engines and aircraft structures as well as for wing skins to achieve the requirements of the new generation of intercontinental aircraft.

Laser peen forming essentially performs the same role as Peen Forming, but because of the greater depth of plastic work, extends the degree of curvatures possible enabling more fuel efficient profiles to be achieved.

Potential applications have also emerged for automotive, power generation, nuclear waste disposal, drilling, medical implants and recreational sports.

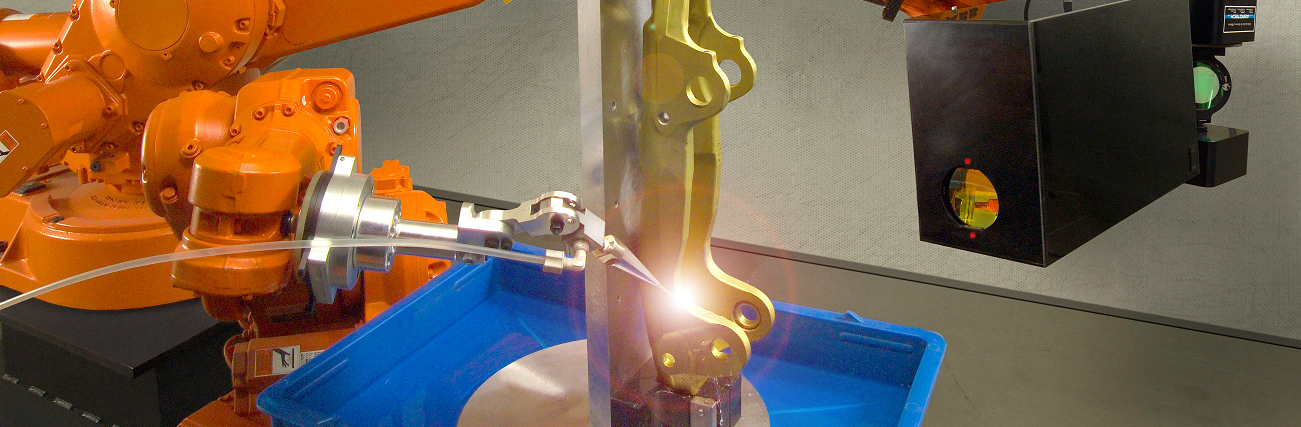

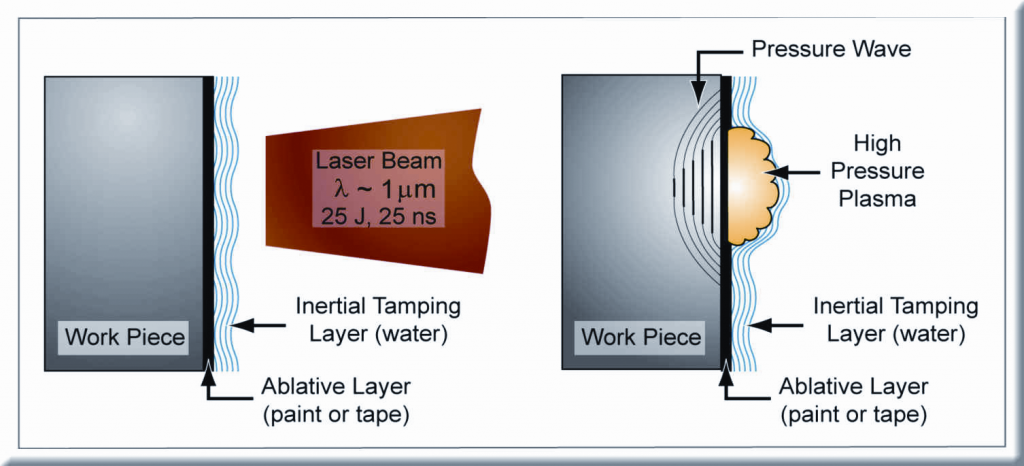

An output beam, roughly 25 Joules at 18 nanoseconds from a Nd:glass laser is projected onto a work piece to induce a residual compressive stress. The area to be peened can be covered with material to act as an ablative layer and simultaneously as a thermal insulating layer, or peened directly onto the base metal which subsequently may require some form of surface removal of a few microns.

An output beam, roughly 25 Joules at 18 nanoseconds from a Nd:glass laser is projected onto a work piece to induce a residual compressive stress. The area to be peened can be covered with material to act as an ablative layer and simultaneously as a thermal insulating layer, or peened directly onto the base metal which subsequently may require some form of surface removal of a few microns.

A thin stream of water is made to flow over the surface, the laser light transparently passes through the water and the leading temporal edge of the laser pulse is absorbed on the metal surface or ablative layer. This absorption rapidly ionizes and vaporizes more of the surface material to rapidly form a plasma that is highly absorbing for the rest of the laser pulse.

A high plasma builds to approximately 100kBar (1 million pounds per square inch) with the water serving to inertially confine the pressure. This rapid rise in pressure effectively creates a shock wave that penetrates into the metal, plastically straining the near surface layer.

The plastic strain results in a residual compressive stress that penetrates to a depth of between 1mm and 8mm depending on the material and the processing conditions. This deep level of compressive stress creates a damage tolerant layer and a barrier to crack initiation and growth, which consequently enhances the fatigue lifetime and provides resistance to stress corrosion cracking and fretting fatigue.

Multiple firings of the laser in a pre-defined surface pattern will impart a layer of residual compressive stress at and below the surface. The process can be tailored to suit the product and potential failure mechanism or enable higher potential loads through weight sensitive designs.

Multiple firings of the laser in a pre-defined surface pattern will impart a layer of residual compressive stress at and below the surface. The process can be tailored to suit the product and potential failure mechanism or enable higher potential loads through weight sensitive designs.

The benefits of an exceptionally deep residual compressive layer are shown above. The S-N curve shows fatigue test results of 6061-T6 aluminum. The testing consisted of unpeened, shot peened and laser peened specimens.

© 2025 Curtiss-Wright Corporation | User agreement | Privacy Policy | Cookies | Sitemap