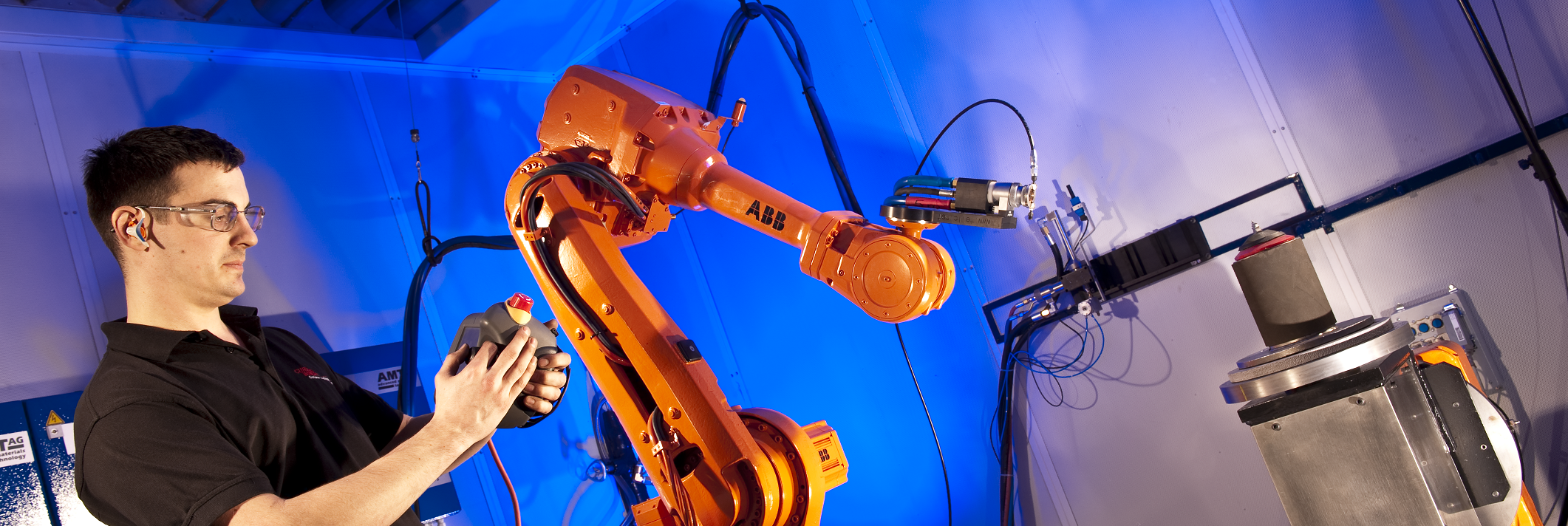

Used in the aerospace, automotive, power generation and oil and gas industries, Curtiss-Wright’s thermal spray coating services include HVOF (High Velocity Oxy-Fuel), plasma, flame and arc spray coatings which produce a cost effective and high performing finish that protects components from heat, wear, corrosion, fatigue and oxidation. HVOF (High Velocity Oxy-Fuel) Coatings are a viable alternative for hard chrome plating.

Damaged and worn parts such as gas and steam turbines can be repaired to original specification.

There are a number of benefits in using thermal spray technology over more traditional coating methods and these include:

Powder particles (typically 1 to 50 microns) are heated to a molten or semi-molten state and are propelled at high velocity, using kinetic energy formed from a gas stream, onto the surface and forms a splat.

Powder particles (typically 1 to 50 microns) are heated to a molten or semi-molten state and are propelled at high velocity, using kinetic energy formed from a gas stream, onto the surface and forms a splat.

This splat then contracts as it cools forming a bond with the surface.

Each splat deposited builds up in layers to the required thickness and density.

Watch our Video showing the Thermal Spray process.

© 2025 Curtiss-Wright Corporation | User agreement | Privacy Policy | Cookies | Sitemap