Suitable for metals, elastomers, electronics and plastics and used extensively in the automotive, aerospace, electronics and medical industries, Parylene Coating is an ultra-thin film polymer coating which provides a consistent pin-hole free barrier coating all shapes, edges, crevices and recesses to the same thickness without suffering any of the edge effects of conventional coatings.

Benefits of Parylene coating

- Ultra-thin film – Coating thickness of less than 1µm can be applied providing sufficient lubricity and barrier protection for most silicone and rubber materials penetrating openings and features as small as 0.01mm

- Pin-hole free barrier – Resistance to chemical attack from organic solvents, inorganic reagents, acids, oxygen and moisture

- Uniform – Thickness tolerances are typically held to ±20% from nominal and tolerances as tight as ±5% are possible even for the most intricate and complex shapes

- Stable – Inert and insoluble in most solvent systems within its temperature range. It is thermally stable between -200°C and 140°C

- Dielectric strength – Extremely high dielectric strength of 5 kV/mil

- Elasticity – Elongation and adhesion of the Parylene film with elasticity above 2x (100%)

- Hydrophobic – Overcomes internal and external fluid build-up in silicone tubes and other components

- Low stress process – Applied at room temperature. Any object which can be exposed to medium vacuum can be coated with Parylene

- Dry Film Lubricant – Eliminates the need for liquid release agents

- Optical clarity – Parylene C is optically clear

- Sterilisation – Coated devices may be sterilised with steam, ETO (Ethylene Oxide Sterilisation) or radiation

- FDA – Parylene is FDA approved

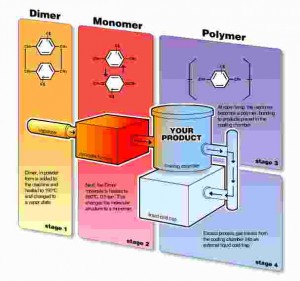

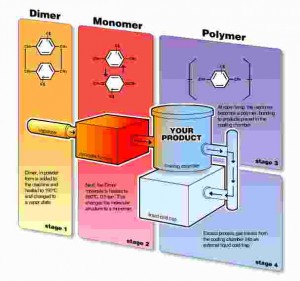

The application process for Parylene coating

Parylene is applied by vapour deposition under a vacuum in a coating chamber at room temperature. The coating process exposes objects to a gas-phase monomer at low pressure. Through vacuum deposition, Parylene condenses and polymerizes on the object’s surface in a polycrystalline formation. The Parylene coating grows at a rate 0.2µm – 0.3µm per minute depending on type N or C respectively.

Parylene is applied by vapour deposition under a vacuum in a coating chamber at room temperature. The coating process exposes objects to a gas-phase monomer at low pressure. Through vacuum deposition, Parylene condenses and polymerizes on the object’s surface in a polycrystalline formation. The Parylene coating grows at a rate 0.2µm – 0.3µm per minute depending on type N or C respectively.

Parylene C is most widely used as it has good electrical and physical properties.

Parylene N is selected for its high dielectric strength and where greater coating penetration is needed.

Parylene coating is normally applied using a batch process where parts are put into a chamber, either horizontal (tumbler) or vertical. The batch process offers a cost effective solution for many applications.

Applications for Parylene coatings

Medical

- Stents

- Catheters

- Mandrels

- Cardiac assisted implantable devices

- Sensors

- Ultrasound transducers

- Guide wires

- Needles

- Epidural probes

- Elastomer components such as Silicone and latex components

Solutions

For medical devices requiring biomedical compatibility and barrier protection against biofluids, moisture and chemicals.

Also acts as a dry film lubricant with a coefficient of friction measurement that approaches that of TEFLON®.

Parylene type N is typically used in applications requiring this type of releasability or dry film lubricant.

Solution

Even and consistent barrier coating which does not pull away from the edges or exhibit meniscus forces.

Excellent dielectric strength.

Resistant to humidity and practically insoluble in all known organic and inorganic solvents including acid and alkali.

Wire Wound Device

- magnets

- wire wound ferrite cores

- powdered ferrite cores

Solutions

Elimination of abrasion damage to the wire along with uniform coating thickness

Maximum winding window.

Low water vapour transmission provides excellent corrosion protection.

Eliminates magnetostrictive or permeability problems.

Rubber

- Elastomer components

- Rubber keyboard and controls

Solutions

Conforms to surface features including internal dimensions of holes.

Strong surface adhesion and elasticity.

Removes elastomer tack and protect against dirt, oils, petrochemicals and solvents.

Protects printed legends from wear.

Parylene is applied by vapour deposition under a vacuum in a coating chamber at room temperature. The coating process exposes objects to a gas-phase monomer at low pressure. Through vacuum deposition, Parylene condenses and polymerizes on the object’s surface in a polycrystalline formation. The Parylene coating grows at a rate 0.2µm – 0.3µm per minute depending on type N or C respectively.

Parylene is applied by vapour deposition under a vacuum in a coating chamber at room temperature. The coating process exposes objects to a gas-phase monomer at low pressure. Through vacuum deposition, Parylene condenses and polymerizes on the object’s surface in a polycrystalline formation. The Parylene coating grows at a rate 0.2µm – 0.3µm per minute depending on type N or C respectively.