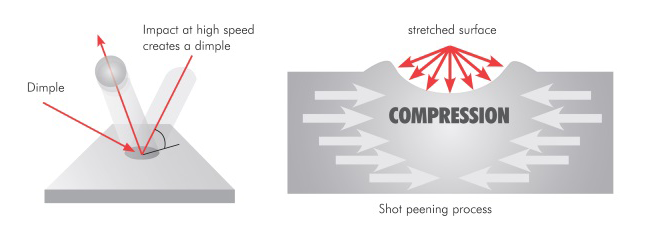

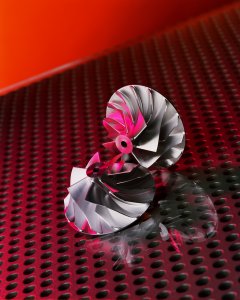

Component failure is often related to residual tensile stress induced during manufacture and certain operating conditions. The controlled shot peening process is a cost effective and practical method of replacing tensile stress with beneficial compressive stress which is proven to prevent failures due to:

Controlled shot peening is a cold working process applied using spherical media known as shot. As each piece of shot hits the surface it creates an indentation where the surface will attempt to yield but is restrained by the substrate material. This conflict causes the substrate material to compress creating a beneficial compressive residual stress which makes the surface resistant to crack initiation and propagation and in the process removes any prior manufacturing tensile stresses.

Each application is specified prior to processing which takes into account:  geometry, manufacturing method, base material, strain sensitivity, in-service environment and loading conditions, as well as costs and turnaround time.

geometry, manufacturing method, base material, strain sensitivity, in-service environment and loading conditions, as well as costs and turnaround time.

When these parameters have been established, the required depth of compressive layer, choice and size of media, intensity and coverage and required surface stress will be calculated and tested, ensuring that any repeat work is carried out to the same specification as the original application.

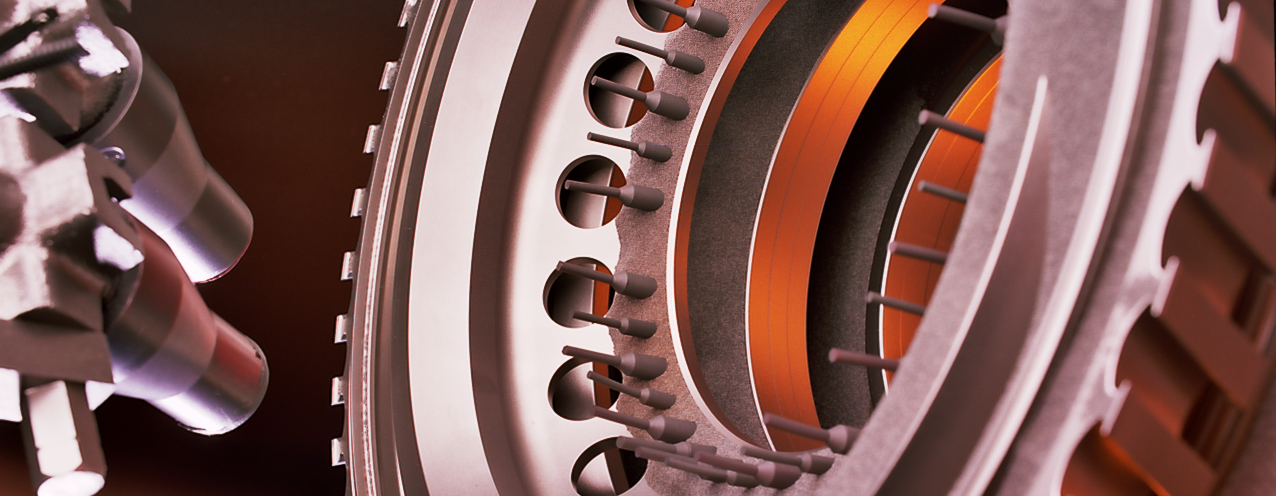

The majority of our processing is carried out using specialist robotic equipment which has been designed in-house, ensuring that the motion of the component to shot flow is consistent.

© 2025 Curtiss-Wright Corporation | User agreement | Privacy Policy | Cookies | Sitemap